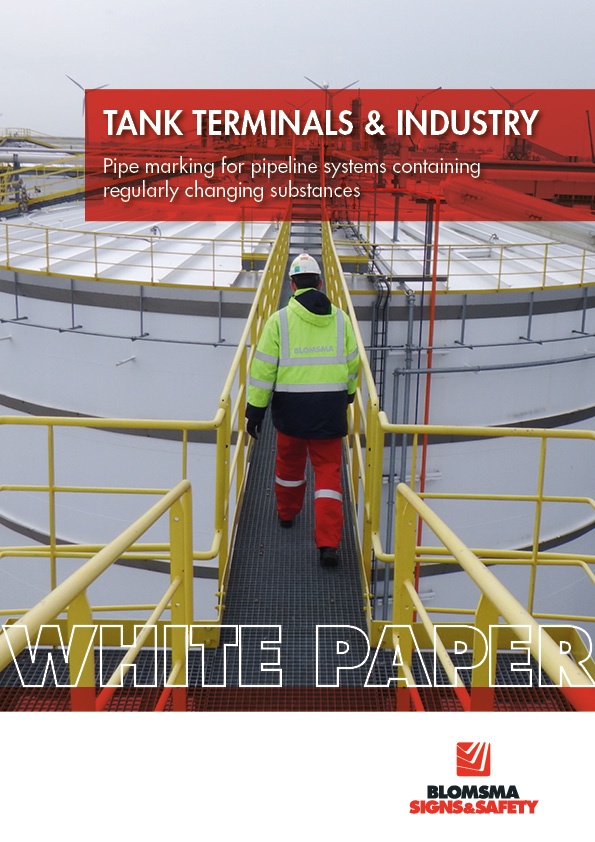

Pipe marking for pipeline systems containing regularly changing substances

Download white paper

The climate of global safety is making ever greater strides forward. This is on the one hand due to incidents and improved oversight, and on the other it is a development in safety-consciousness and companies’ efforts to achieve higher safety standards. A legal framework has been set up that is consulted by both companies and supervisory authorities. However, this framework cannot always be translated clearly into practical solutions.

In this white paper, we take a closer look at pipe marking for pipeline systems that contain regularly changing substances. We describe the challenges and risks that come with pipes containing changing substances and the applicable legal requirements and norms. But we also show you some practical solutions that we can help you implement.

Gate LNG Terminal

Gate terminal is very concerned about health, safety and the environment, operating a strict policy. That is why Blomsma Signs & Safety began an inventory early in 2015 at Gate terminal BV with the aim of getting a clear picture of the signage that was present plus what was required. A signage plan was then drawn up using that study and priorities were set for reconstructing the safety signage.

The first phase consisted of sorting out the pipe and tank markings, removing old or weathered markings and applying new ones at logical points. The same was then done for the new dock where LNG is bunkered for the shipping sector.

TAQA Energy Gasopslag Bergermeer

During construction, a detailed sign plan is engineered for the Boekelermeer (compressor station) and Bergermeer (wellsite) sites, which is realized after a thorough evaluation. Central to the plan was the link between regulatory requirements for health and safety signage, and the physical needs of the users, the target group for which the signage is implemented.